1.Assemblea sheet and press both inner bearing race against shoulder until contact is obtained.

2. Insert outer bearing race(Figure 254) into the housing bore until contact is obtained.

3. Position screening plate.

4. Insert output shaft.

5. Fasten both sheets using socket head screws (4x).

NOTE: Insert socket head screws with Loctite (Type

No. 243).

NOTE: Torque limit (M8/8.8) 2.35 kg•m (17 ft lb)

Caterpillar ET 2022A Electronic Technician Diagnostic Software

6. Squeeze rectangular rings (6x) into the recesses of the

clutch shafts and hook them in.

7. Grease rectangular rings and align them centrically

8. Insert both O-rings (Figure 259) into the annular groove of

the oil pipes and grease them.

9. Cover mounting face with sealing compound Loctite #574.

10. Install adjusting screws (S) and position housing cover

carefully against gearbox housing until contact is obtained,

using lifting device.

NOTE: Pay attention to the overlapping of the oil pipe

with the bores in the housing cover.

(S) Adjusting screws - 5870 204 007

11. Install both cylindrical pins

(S) Lifting chain - 5870 281 047

Doosan Diagnostic Tool DDT G2

12. Fasten housing cover using hex. head screws.

NOTE: Torque limit (M10/8.8) 4.69 kg•m (34 ft lb).

NOTE: Pay attention to the position of the fixing plate,

see Figure 262.

13. Install shaft seal, with the sealing lip facing the oil chamber.

NOTE: By application of the prescribed driver, the exact

installation position is obtained. Wet rubber

coated outer diameter with spirit. Grease

sealing lip.

(S) Driver - 5870 048 057

14. Heat the output flange (Max. 90°C (194°F)), assemble it

and attach it using washer and hex. head screws.

NOTE: Wet contact area of washer with sealing

compound Loctite (Type No. 574).

NOTE: Torque limit (M8/10.9) 3.47 kg•m (25 ft lb).

15. Assemble both axial washers and needle cage.

NOTE: Upper and lower axial washer have the same

thickness (50x 70x 1).

16. Assemble both needle bearings

17. Assemble idler gear.

18. Assemble axial washer (3, Figure 229) (50 x 70 x 1) needle

cage (2) and running disk (1) (50 x 70 x 4).

NOTE: Install running disk 1 with the chamfer facing the

needle cag

19. Assemble pre-assembled plate carrier until all inner plates

are accommodated

20. Attach plate carrier axially using retaining ring.

(S) Set of external pliers - 5870 900 015

(S) Handle - 5870 260 010

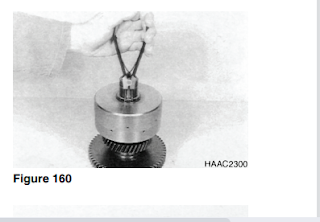

21. Press tapered roller bearing against shoulder.

22. Install opposite tapered roller bearing

Doosan Daewoo Excavator Operation and Repair Manual PDF

NOTE: With correctly installed components, the

closing, reap. opening of the clutch is clearly

audible.