This article describes the disassembly of John-Deere 3029, 4039, 4045, 6059, 6068 Engines (Saran)-499999CD

ENGINE DISASSEMBLY SEQUENCE

The following sequence is suggested when complete

disassembly for overhaul is required. Refer to the

appropriate repair group when removing individual

engine components.

1. Drain all coolant and engine oil. Check engine oilfor metal contaminates (see Groups 25 and 30).

2. Remove fan belts, fan, and alternator (seeGroup 30).

3. Remove turbocharger (if equipped) and exhaust manifold (see Group 35).

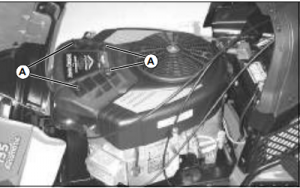

4. Remove rocker arm cover with vent tube. On engines having an Option Code label on rocker arm cover, be careful not to damage label (see Group 05).

5. Remove water manifold with thermostats (see Group 30).

6. Remove oil cooler piping and water pump (seeGroups 25 and 30).(Continued on next page)

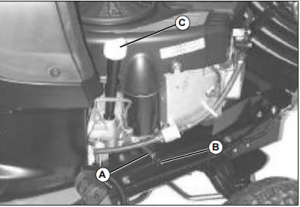

7. Remove dipstick, oil filter, and engine oil cooler.

Discard standard-flow oil cooler if oil contained metal

particles (see Group 25).

8. Remove oil pressure regulating valve assembly(see Group 25).

9. Remove fuel filter, fuel transfer pump, and fuel lines (see Group 40).

10. Remove injection lines, injection pump, andinjection nozzles (see Group 40).

11. Remove starting motor.

12. Remove rocker arm assembly and push rods.Keep rods in sequence (see Group 05). Check forbent push rods and condition of wear pad contactsurfaces on rockers.

13. Remove cylinder head. Check piston protrusion.Verify piston height selection (see Groups 05 and10).

14. Remove cam followers. Keep in same sequence as removed (see Group 20).

15. Remove oil pan (see Group 25).

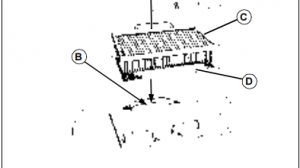

16. Remove flywheel and flywheel housing (see Group 15).

17. Remove crankshaft pulley (see Group 15).

18. Remove timing gear cover (see Group 20).

19. Remove oil pump drive gear, outlet tube (and its O-ring in block) and pump body (see Group 25).

20. Remove oil slinger, timing gears and camshaft.Perform wear checks (see roup 20).

21. Remove balancer shafts (4-cylinder only, if equipped), see Group 20.

22. Remove engine front plate (see Group 20).

23. Remove lube oil system by-pass valve (see Group 25).

24. Stamp cylinder number on rod (if required). Remove pistons and rods. Perform wear checks with “PLASTIGAGE”. On 4 and 6-cylinder engines, remove two at a time (see Group 10).

25. Remove main bearings and crankshaft. Perform wear checks with PLASTIGAGE” (see Group 15).

26. Remove cylinder liners and mark each one with cylinder number from which removed (see Group 10).

27. Remove piston cooling orifices (see Groups 10 and 15).

28. Remove balancer shaft and camshaft bushings (if equipped), see Group 20.

29. Remove cylinder block plugs and serial number plate (as required) when block is to be put in a “hot tank” (see Group 10).

30. Clean out liner bores (upper and lower areas) with nylon brush (see Group 10).

31. Measure cylinder block (see Groups 10, 15, and 20)

02.2024 John Deere Parts ADVISOR EPC(CF& AG& CCE)