Translate

2024年1月3日星期三

How to Remove Cummins M11 Turbocharger and Oil Return Pipe

2023年12月30日星期六

How to Disassemble Cummins M11 Series Engine Accessories

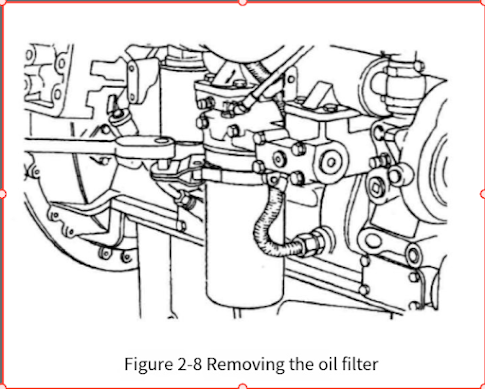

This article mainly introduces how to disassemble Cummins M11 series engine accessories ①Close the coolant valve and use a wrench (part number 3376807) to remove the coolant filter, see Figure 2-7. ② Use the oil filter wrench to remove the oil filter, see Figure 2-8.

③ Use a wrench (part number 3376807) to remove the fuel filter, see Figure 2-9. ④ Loosen the locking nut on the fan idler pulley shaft, rotate the adjusting screw to release the tension of the transmission belt, and remove the fan drive belt, see Figure 2-10.

Cummings INLINE 6 Diagnostic Adapter for Heavy Duty Truck High Quality

⑤ If an electronic fan clutch is used, remove the fan clutch connector from the wiring harness, see Figure 2-11. ⑥Remove the 6 bolts and fan, see Figure 2-12. ⑦ Remove the 4 bolts and fan pulley, see Figure 2-13.

CUMMINGS INPOWER PRO 14.5 Diagnostic Software with 2023.6 PGA by remote installation

2023年12月21日星期四

How to Disassemble Cummins M11 Engine engine Accessories

This article w How to disassemble Cummins M11 engine engine accessories

① Close the coolant valve and use a wrench (part number 3376807) to remove the coolant filter, see Figure 2-7.

② Use the oil filter wrench to remove the oil filter, see Figure 2-8.

Cummings Insite 8.7 Pro Diagnostic Software Download and Installation

③ Use a wrench (part number 3376807) to remove the fuel filter, see Figure 2-9. ④ Loosen the locking nut on the fan idler pulley shaft, rotate the adjusting screw to release the tension of the transmission belt, and remove the fan drive belt, see Figure 2-10.

CUMMINGS INPOWER PRO 14.5 Diagnostic Software with 2023.6 PGA by remote installation

⑤ If an electronic fan clutch is used, remove the fan clutch connector from the wiring harness, see Figure 2-11.

⑥Remove the 6 bolts and fan, see Figure 2-12.

⑦ Remove the 4 bolts and fan pulley, see Figure 2-13.

2023年11月12日星期日

How to Troubleshoot the Problem That the Coolant Temperature of the Excavator's Electronically Injected Diesel Engine is Too High

1. Cause of failure

(1) The radiator fins are dirty, debris or damaged.

(2) Insufficient coolant.

(3) The radiator cap or pressure relief valve is damaged.

2023 CAT ET 2023A 2022A & 2019C Full Service Download and Installation Service

(4) There is air in the cooling system.

(5) The cooling fan is not working properly and the fan belt is too loose.

(6) The thermostat is damaged.

(7) The cooling system pipeline is blocked or leaking.

(8) The coolant temperature gauge is damaged.

(9) The water pump impeller is damaged or corroded.

12.2021 Caterpillar ECM ECU Flash Files Full Set Download

2.Fault

(1) Visually inspect the cooling system for broken hoses or other throttling components.

(2) Check the radiator fins for dirt, debris and damage. Remove dirt and debris, clean and flush the radiator, and straighten any bent fins.

(3) Check the coolant level and add coolant if necessary.

(4) Check whether the cooling system is leaking and repair the leaking area immediately.

(5) Check the cooling system pressure.

(6) Check the pressure relief valve and radiator cap. Clean and replace parts if necessary.

Caterpillar CAT Factory Password Calculator Generator 10 Digits VM Version

(7) Check whether the seat surface of the pressure safety valve and the radiator cover are clean and damaged.

(8) Check whether there is combustion gas in the cooling system and whether there are bubbles in the coolant. If there are bubbles, combustion gases may have entered the cooling system.

(9) Check whether the cooling fan is working normally. Check that the belt and pump are working properly.

(10) Check whether the thermostat is operating correctly. If necessary, replace the thermostat.

(11) Compare the coolant temperature reading from the ET to the coolant temperature reading from the mechanical measuring instrument.

(12) Check whether the water pump impeller is damaged or corroded. Repair or replace water pump if necessary.

(13) Check whether the fault is caused by system overload, reduce the load and check whether the condition recurs.

CAT Caterpillar ET 4 Diagnostic Adapter Truck Diagnostic Tool-high quality

2023年11月9日星期四

How to Disassemble Cummins Engine Turbocharger and Oil Return Pipe

How to disassemble cummins M11 engine turbocharger and oil return pipe

① Remove the oil supply pipe and sealing gasket from the top of the turbocharger, remove the other

Cummings Insite 8.7 Pro Diagnostic Software Download and Installation

end of the oil supply pipe from the oil filter seat, and then remove the oil return pipe and sealing gasket

from the bottom of the turbocharger, see Figure 2-22.

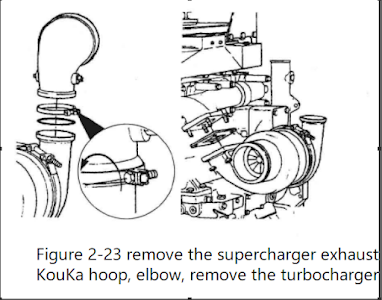

② Remove the V-shaped clamp, exhaust elbow and O-ring from the exhaust port of the turbocharger

compressor, remove 4 mounting nuts, remove the turbocharger and gasket, and block the supercharger

For the oil supply hole and oil return hole, see Figure 2-23.

Cummings Insite 8.7 Pro Diagnostic Software Download and Installation

③ Remove the turbocharger oil return pipe joint, see Figure 2-24.

2023年11月4日星期六

How to Solve the Problem of Doosan Excavator Turning to the Right Slowly and Unable to Brake

How to solve the problem of Doosan excavator turning to the right slowly and unable to brake

Doosan Diagnostic Tool UVIM Support Doosan Excavators High QualityApplicable models: All models Phenomenon: The turning speed and braking to the left are normal, but the turning speed to the right is slow and the car cannot be braked.

1. Inspection essentials:

A. The one-way rotation is normal to eliminate the problem of the main pump.

B. Check the pressure during rotation overflow, which is 285BAR to the left and 190BAR to the right,

which is lower than the standard value of 280BAR.

C. Adjusting the left and right rotation relief valve has no effect, indicating that it has nothing to do

with the relief valve.

D. Check the oil supply one-way valve on the right side of the rotary motor and find that the one-way

valve is stuck in the normal position. Take out the one-way valve and grind it. After installation and

test run, it is normal.

2023.07 Doosan DMS-5 Data Monitoring System Diagnostic Software

2. Cause: The one-way valve is stuck in the normal position, causing a large amount of hydraulic oil

leakage in the right chamber, resulting in low pressure and slow speed.

3. Treatment method: Take out the stuck one-way valve and grind it, OK

2020 Doosan Daewoo Excavator Operation and Repair Manual PDF

How to Deal with The Oil Leakage Problem of Doosan Excavator Cylinder Oil Seal

How to deal with the oil leakage problem of doosanDH220LC-V excavator cylinder oil seal

Doosan Diagnostic Tool UVIM Support Doosan Excavators High Quality

Applicable to all models

Phenomenon: The oil seal of the hydraulic cylinder leaks oil and causes serious pollution.

1. Inspection essentials: disassemble and inspect the oil seal of the cylinder and analyze the damage of the oil seal:

A The oil seal is blackened, loses elasticity, and is severely carbonized.

2023.07 Doosan DMS-5 Data Monitoring System Diagnostic Software

B. The oil seal has one or several scratches, and oil leaks from the scratches.

C. The oil seal circumference is damaged in a large area, and the cylinder rod is seriously scratched.

Doosan Diagnostic Tool DDT G2 SCAN( ECU ,DCU)Software 2016

2. Reason A. The air in the cylinder is not evacuated before operation, and high temperature is generated under the action of high pressure, resulting in carbonization of the oil seal.

B. There are debris particles in the cylinder, which will scratch the oil seal and cylinder rod.

C. The oil seal is damaged due to severe scratches on the cylinder rod.

3·Processing method:

A. Replace the oil seal; avoid violent and large-scale operations before the oil cylinder moves, and try to exhaust the air in the cylinder rod as much as possible.

B. Replace the oil seal with a new one to ensure the quality of the hydraulic oil and keep the hydraulic system clean.

C. Replace the scratched cylinder rod and oil seal.

How to remove the rear steering label axle from a Scania 4 Series truck

IMPORTANT! Handle empty accumulator tanks in compliance with local regulati ons. 12.2025 Scania SDP3 2.68.2 Diagnosis & Programmin...

-

This instruction shows you how to adjust the accelerator lever for Kubota U10 U20 excavators. 2022 Kubota Takeuchi DiagMaster Level ...

-

This article mainly introduces the installation of DEF injector for Perkins 2806F-E18TA industrial engine diesel engine Perkins Engine ECM...

-

This article mainly introduces Lift Trucks and Skid Steer Loaders Cummins Engine Disassembly Cummins INSITE 8.7 Pro 2021 Elec...