This article mainly introduces YANMAR maring diesel engine 3JH2 Series Governor disassembly

Yanmar Engine Diagnostic Service Tool Software

NOTE: Loosen the hex bolt on models with an angleich spring.

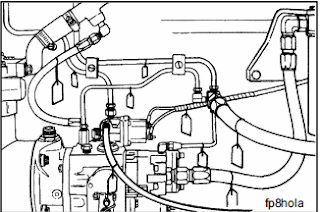

(2) Remove the control lever hex nut, and pul out the con-

trol lever from the control lever shaft.

(3) Remove the governor case bolt. Remove the governor case(parallel pin) from the fuel pump until while lightly tapping the governor case with a wooden hammer.

Create a gap between the governor case and fuel pump by moving parts of the governor lever.

(4) Pull out the governor link snap pin by inserting needle nosed pliers between the fuel pump and governor case.

case.

(5) The governor and fuel pump come apart by sliding the governor case and fuel pump apart and pulling out the link pin of the fuel control rack.

(6) Remove the stop lever return spring from the governor lever shaft.

For Yanmar Diesel Engine Agriculture Excavator Tractor Marine Generator Diagnostic tool

(7) Use needle nose pliers to unhook the governor spring from the tension lever and control lever shaft.

(8) Remove the snap-rings on both ends of the governor lever shaft.

(9) Put a rod 8mm (0.3150in.) in dia. or less in one end of the governor lever shaft, and tap the governor shaft until the O. ring comes out the other side of the govermor case.

(10) Atter removing the O-ring, lightly tap the end of the shaft that you removed the O-ring from, and removethe governor lever shaft. Then remove the governor shaft assembly and washer.

(11) Remove the governor link from the governor lever.

(12) When you need to pull out the stop lever, remove thestop lever shaft stop pin, and lightly tap the inside of the governor case.

(13) When you need to pull out the control lever shaft, tap the end of the shaft with a wood hammer.

(15) Turn the governor weight with a box spanner two or three times to loosen it, stopping it with the hole inthe fuel coupling ring or holding the coupling with a vise.

(16) Remove the governor weight assembly from the fuel pump cam using the governor weight pulling tools.

NOTE: The governor weight assembly is made up of the governor weight, support and pin. Do not dis.

assemble.

For Yanmar Diesel Engine Agriculture Excavator Tractor Marine Generator Diagnostic tool