This article mainly introduces Lift Trucks and Skid Steer Loaders Cummins Engine Disassembly

Cummins INSITE 8.7 Pro 2021 Electronic Service Diagnostic Software

NOTE: Put tag on all hoses, lines, linkage, and electrical connections as they are removed to identify location and aid the installation process.

A WARNING Always disconnect the negative(-) cable first.

Disconnect the battery cables.

A WARNING Allow the engine to cool before draining to avoid burns from hot liquid.

AWARNING Coolant is toxic. Keep away from children and animals. Save for reuse or dispose of in accordance with local regulations.

Drain the engine coolant.

AWARNING Some state and federal agencies in the United States of America have determined that used oil is carcinogenic and can cause reproductive toxicity. Avoid inhalation of vapors, ingestion, and prolonged contact with used engine oil. Always use the proper procedures to dispose of the oil.

Drain the lubricating oil.

Engine Oil:7.5 liters [1.98 U.S. ga]

Disconnect the starter cable, engine ground straps, cab or chassis to engine hoses, tubing, electrical wires and hydraulic lines.

Disconnect the drive units from the flywheel housing and flywheel.

Remove all chassis components necessary to remove the engine from the equipment.

Prepare a stable stand, Part No.3375193 or 3375194, which will prevent the engine from falling over.

Engine Weight(approx.):255kg [562 b]

Cummins INLINE 6 Data Link Adapter Truck Diagnostic Tool

Remove the starting motor.

Install the bracket, Part No.3163625, on the engine.

A WARNING This component weighs 23kg [50 Ib] or more. To avoid personal injury, use a hoist or get assistance to lift this component. The engine lifting equipment must be designed to lift the engine without causing personal injury.

Put the engine on the stand.

Cover all the engine openings to prevent dirt and debris from entering the engine.

Fan Pulley AWARNING Be careful not to injure your fingers or damage the alternator when moving the alternator toward the cylinder block.

Loosen the mounting capscrew of the adjustment plate(1). Loosen the alternator mounting capscrew and nut.

Move the alternator toward the cylinder block, and remove the belt (2).

Remove the fan pulley.

Fan Remove the four capscrews, retainer plate, fan, and spacer.

Alternator Remove the adjusting capscrew and washer.

Remove the capscrew, adjustment plate, and spacer.

Remove the remaining capscrew and alternator.

Lubricating Oil Filter

Remove the lubricating oil filter.

Dipstick Guide

Remove the dipstick and dipstick guide.

Water Pump

Remove the mounting capscrews, water pump, gasket, and o-ring.

Discard the gasket and o-ring.

Themostat Remove the two mounting capscrews,thermostat housing,thermostat and seal

Exhaust Manifold Remove the eight capscrews, exhaust manifold, and gasket.

Discard the gasket.

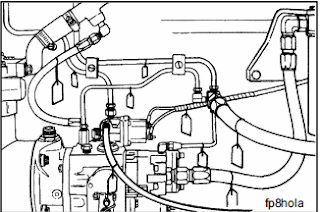

Fuel lnjection Tubing Remove the clamp.

Remove the sleeve nuts and the fuel injection tubing from the fuel injection pump and the cylinder head.

Intake Manifold Remove the eight capscrews, intake manifold, and air inlet connection. Remove the grid heated, if equipped.

Remove the four capscrews, air inlet connection, and o-ring. Discard the o-ring.

Spill Tube

Remove the spring hose clamps and hose.

Remove the spill tube.

Injector A CAUTION Be careful not to damage the tip of the injector when removing.

Remove the mounting capscrew, washer, and injecdor.

NOTE: When removing the injector, clean around the injector, and insert a blind plug to prevent dust or dirt from entering the engine.

NOTE: Mark the injectors with tags showing the cylinder number, and keep it in a safe place.

If there is no abnormality in the injector, install it in the same position during assembly.

Rocker Lever Cover Remove the three capscrews, isolator assemblies, rocker lever cover, and o-ring.

没有评论:

发表评论