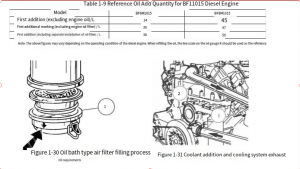

(1) Preparations before starting the diesel engine For the BFM1015 diesel engine, the following points should be noted when the new engine is put into use for the first time. ① Fill the diesel engine with qualified engine oil Before using the diesel engine, fill it with qualified engine oil that meets the use requirements of the diesel engine (the quality grade and viscosity requirements of the engine oil can be referred to the instruction manual of the diesel engine. If there is no reference material, it is recommended to use heavy-duty diesel engine oil of CF grade or above. The viscosity requirement is determined according to the ambient temperature. If it is used in the southern region for a long time, it is recommended to use 15W/40). The reference amount of engine oil is shown in Table 1-9.

Deutz Diagnostic Tool Communicator for Deutz Engine DECOM Controllers

② Filling the Oil Bath Air Filter with Engine Oil

Figure 1-31 Coolant Filling and Cooling System Venting

If this diesel engine is equipped with an oil bath air filter,

Before use, fill the air filter oil bowl 1 (see Figure 1-30) with engine oil of the same grade as the diesel engine to the line marked with the arrow.

b. Filling and Venting the Cooling System. Connect the water tank to the diesel engine's water inlet pipe 1 and water outlet pipe 2, as shown in Figure 1-31. Then, fill with coolant. Start the diesel engine and run it to normal operating temperature, i.e., the thermostat opens (pipe 2 becomes hot). At this point, check the fluid level in the cooling system and top up if necessary. c. Cooling System Protective Fluid. If conditions permit, add cooling system protective fluid to the cooling system. Cooling system protective fluid provides effective protection against rust, cavitation, and freezing, significantly extending the service life of the diesel engine's cooling system. The concentration of protective fluid in the coolant should not fall below or exceed the limits specified in Table 1-11. Table 1-11 Concentration requirements for cooling system protective fluid

![]()

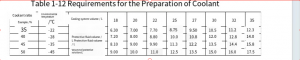

d. Coolant preparation requirements. Coolant preparation requirements and their corresponding ambient temperatures are shown in Table 1-12.

2024 Deutz SerDia 4.0 SerDia2010 14.1.9.3 Highest Level 6 Diagnostic Software

(2) Starting, operating and stopping the diesel engine ① Diesel engine starting preparation Before starting, in addition to correctly adding engine oil, diesel and coolant, checking the connection status of each connection part and checking the customer instructions, the following preparations should also be carried out.

a. Check the battery and battery connection cable.

b. When starting with a flame preheating plug, no other auxiliary starting method (such as starting fluid) is allowed.

c. Never start the diesel engine with the governor removed.

② Starter use requirements The starter power-on time should not exceed 20 seconds at a time. If the diesel engine cannot start, wait 1 minute and try again. If the diesel engine fails to start successfully after two attempts, it is necessary to check the cause; start again after the cause is identified and the fault is eliminated.

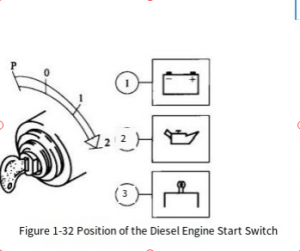

③ Diesel Engine Starting Procedure a. Disengage the clutch to disconnect the drive equipment from the diesel engine. b. Use the hand lever or foot pedal to move the throttle handle to the medium speed position. c. Insert the key (as shown in Figure 1-32) and turn the key clockwise to position

1. The charge indicator and oil pressure indicator will illuminate. Continue turning the key clockwise to position

2. The starter motor will start. d. Immediately after the diesel engine ignites, release the key. The oil pressure and charge indicators will go out (normal temperature start). e. Cold Start: When the temperature is below 0°C, use a glow plug for preheating. Starting aids are not required at lower temperatures, making starting easier. The cold start glow plug operation procedure is as follows: Insert the key and turn it clockwise to position 1. Indicators 1, 2, and 3 will illuminate, and the diesel engine will preheat. Wait until preheat indicator 3 flashes (maximum 30 seconds). The diesel engine is now ready to start. Continue turning the key clockwise to position 2 to start the diesel engine. Once the diesel engine starts running, immediately release the key. The indicator light will go out. Slowly decelerate the engine and allow it to operate at a moderate load. Once the engine oil temperature rises, resume high-load operation.

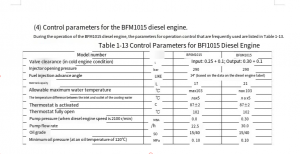

④ Precautions for Normal Diesel Engine Operation: During diesel engine operation, monitor the oil pressure. After the engine is started, the oil pressure should be greater than 0.1 MPa and no less than 0.3 MPa at the rated speed. At this time, the charging indicator and oil pressure indicator should go out, and the coolant temperature gauge needle should be in the green zone. If any abnormality is detected, stop the engine and inspect it. During operation, avoid sudden accelerator pedaling, sudden acceleration and deceleration, or sudden stops from full load. Also, avoid operating the engine at low temperatures (referring to the diesel engine temperature) for extended periods, such as prolonged idling, as this can cause premature wear. Diesel engines consume some oil during normal operation and require timely oil addition. However, simply adding oil without regular oil changes is prohibited. During operation, always pay attention to whether the oil pressure and coolant temperature are normal. After work, if the engine is stored outdoors for a long time, pay attention to prevent rainwater from entering the fuel tank, exhaust pipe, intake pipe, etc. to avoid malfunctions. Tips: Ensuring that the air filter, oil filter and diesel filter are working reliably, adding oil and coolant that meet the requirements, and using the correct brand of diesel are the keys to ensuring the reliable operation of the diesel engine. ⑤ Diesel engine shutdown requirements The diesel engine must not be suddenly stopped from full load conditions. After unloading, it should be idle for a short time to stabilize the temperature before stopping. At this time, the charging indicator light and oil pressure indicator light will light up again. Turn the start key counterclockwise and pull it out. The charging indicator light and oil pressure indicator light should go out. (3) Diesel engine running-in requirements New diesel engines and diesel engines that have been overhauled must be run-in before being put into normal use. Practice has shown that the service life, reliability and economy of the diesel engine depend to a large extent on whether the diesel engine has been run-in correctly according to regulations in the early stage of use. The BFM1015 series diesel engine has a break-in period of 200 to 300 hours (depending on usage). Specific requirements are as follows: ① With the throttle at 2/3, operate at 1/4 load for 5 hours, 1/2 load for 5 hours, and 3/4 load for 5 hours. ② With the throttle at full throttle, operate at 1/4 load for 5 hours, 1/2 load for 5 hours, and 3/4 load for 25 hours. Repeat the break-in cycle several times until the predetermined break-in period is reached. ③ A run-in diesel engine can extend its service life and reduce fuel and oil consumption. However, idling or no-load operation is prohibited during the break-in period, as this will not achieve the desired break-in effect. ④ After the 50-hour run-in period, remember to perform an inspection. The main tasks include: draining the engine oil (the engine should be shut down and the oil temperature should be around 80°C), cleaning the oil pan before adding new oil, cleaning or replacing the oil filter or element, checking valve clearance, and inspecting and tightening all major connections, such as the air filter connection pipe, water pipe, and oil pipe. Important Note: Always perform a run-in according to specifications. This will extend the service life of the diesel engine and reduce diesel and oil consumption. During the run-in period, check the oil level twice daily; after the run-in period, check the oil level once daily.

Deutz Serpic 2012 EPC Download & Installation Service Finial Version

没有评论:

发表评论