Preparing the Cab Frame Aperture

1 If damp or wet, dry the aperture area using a hot air gun

(sourced locally).

2 Use 'Active Wipe 205' to thoroughly clean and 'prime'

the trimmed sealant. Use a lint free cloth to apply the

'Active Wipe 205', allow 5 minutes flash off (drying)

time.

Note: Do not use any other type of cleaning fluids, otherwise

they may be absorbed into the old sealant and ultimately

prevent the new glass from bonding.

Direct Glazing (cont'd)

Preparing the New Glass

JCB Electronic Service Tool Diagnostic Kit High Quality

! CAUTION

The laminated front screen must be handled with extra

care to prevent breakage. Wherever possible, store and

handle it in a vertical attitude. When placing or lifting the

screen in a horizontal attitude it must be supported over

its whole area, not just at the edges.

BF 1-8

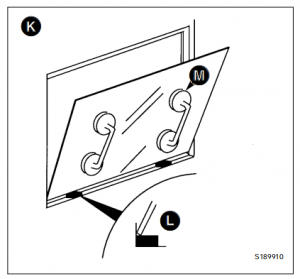

1 Make sure that the new glass correctly fits the frame

aperture K.

a Put two spacer blocks L onto the bottom part of the

frame aperture.

b Install the new glass on the spacer blocks - ALWAYS

USE GLASS LIFTERS M (see Service Tools). Check

that there is an equal sized gap all round the edge of

the glass.

Note: The spacer blocks are rectangular in section to give

two common gap widths. If necessary they can be trimmed

to a smaller size to give an equal sized gap around the glass.

IMPORTANT: The glass edges MUST NOT touch the frame,

otherwise movement of the frame will chip and eventually

break the newly installed glass.

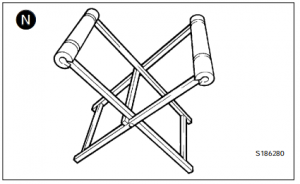

2 After checking for size, remove the new glass and place

it on a purpose made glass stand N (see Service

Tools).

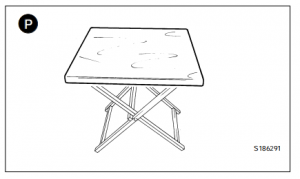

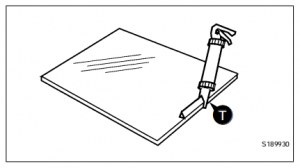

Small panes of glass will need locating on a 600 x 700 mm x

15 to 19 mm thick plywood board P (sourced locally to fit

the glass stand N). It is recommended that an access hole is

cut in the board to accommodate the glass lifter, making it

easier and safer to handle small panes of glass. The board

should be covered with felt or carpet to give an anti-scratch

surface. Resting the glass on four spacer blocks will ensure

clearance of the cartridge nozzle tip during application of the

polyurethane sealant.

3 Make sure the glass is positioned on the stand the

correct way up (i.e. with the black ceramic ink band

upwards) ready for application of primer etc.

4 a Use 'Active Wipe 205' to thoroughly clean and

'prime' the black ceramic ink band printed on the

glass (see Note 1). Use a lint free cloth to apply the

'Active Wipe 205', allow 5 minutes flash off (drying)

time.

Note 1: Do not touch the glass after cleaning with the

'Active Wipe 205'.

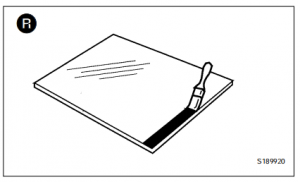

b If the glass does not have a black ceramic ink band,

paint a band on the glass using 'Black Primer 206J'.

The band should be approximately 25mm (1in) wide,

and the edge should be a neat straight line as shown

at R

06.2025 JCB ServiceMaster 4 v25.3.3 Diagnostic Software with SW Files Download and installatiom

Direct Glazing (cont'd)

Preparing the New Glass (cont'd)

5 Install the Ultra Fast Adhesive cartridge (see Sealing

and Retaining Compounds and Note 2 below) into a

suitable applicator gun:

a Remove the aluminium disc cover from the base of

the cartridge and discard the 'dessicant capsule'.

b Make sure that the rolled edge of the cartridge is not

damaged - if necessary, the edges should be

pressed flat, otherwise it will be difficult to remove

the cartridge from the applicator gun.

c Pierce the front 'nozzle' end of the cartridge to its

maximum diameter.

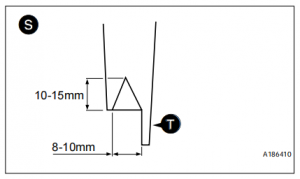

d Fit the pre-cut nozzle shown at S.

e Install the cartridge in the applicator gun.

Note 2: Cold material will be very difficult to extrude. The

cartridges must be pre-heated in a special oven (see

Service Tools) for 1 hour to a temperature of 80°C (176°F).

Pre-heating the cartridges makes the adhesive more

workable and also brings the 'curing' time down to 30

minutes.

6 Apply the pre-heated adhesive to the glass (do not start

in a corner). Keep the nozzle guide T against the edge

of the glass and make sure that the adhesive forms a

continuous 'pyramid' shape.

Note 3: Once the pre-heated adhesive has been applied to

the glass, install the glass in the aperture as soon as

possible. After approximately 10 minutes the sealant will

form a 'skin', this will prevent the glass from bonding.

7 After applying the adhesive, leave a small amount of

sealant protruding from the nozzle. This will prevent any

adhesive left in the cartridge from 'curing'.

Installing the New Glass

1 Make sure the two spacer blocks are in position (see

step 1 of Preparing the New Glass).

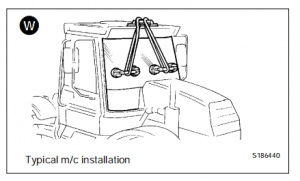

2 Install the glass in the frame aperture:

a ALWAYS use the special lifting tools when moving

the glass. Use a lifting strap to hold large panes of

glass in position as shown W.

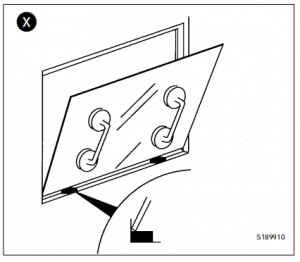

b Sit the bottom edge of the glass on the spacer

blocks as shown X.

c Make sure that the glass is correctly positioned, then

gently press around the edges of the glass and

ensure full adhesive contact is achieved. Do not

press too hard or too much adhesive will squeeze

out.

Direct Glazing (cont'd)

Installing the New Glass (cont'd)

3 Make the inside seal smooth:

a Wearing surgical gloves, dip your finger in a soapy

water solution.

b Use your finger to make the inside seal smooth.

4 All exposed edges must be sealed using Black

Polyurethane Sealant (see Sealing and Retaining

Compounds).

5 Clean the glass after installation:

IMPORTANT: Use extreme caution when wiping the inside

of the new glass - pushing too hard on the inside of the

glass will affect the integrity of the bonded seal.

a Small amounts of sealant can be cleaned from the

glass using the 'Active Wipe 205'.

b Large amounts of excess sealant should be left to

'cure' (see Note 4) and then cut off with a sharp

knife.

Note 4: On completion of the glass replacement procedures,

the sealant 'curing' time is 30 minutes. This means that the

machine can be driven and used after 30 minutes, but it

MUST NOT be used during the curing period of 30 minutes.

c Clean the glass using a purpose made glass

cleaner.

6 On completion of the glass installation procedures tidy

the work area:

a Remove ALL broken glass from the cab area.

b Remove the protective covers from the cab seat and

control pedestals.

c Renew all 'warning' and 'information' decals so that

the new installation conforms with the original cab

installation.

没有评论:

发表评论