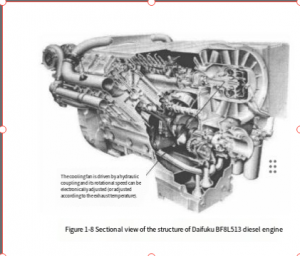

FL513 series air-cooled diesel engine structure introduction Deutz FL513 series diesel engine (as shown in Figure 1-8) marks the beginning of a new era of air-cooled diesel engines. This series of diesel engines uses independent cylinder liners with heat sinks and a one-cylinder-one-head modular structure. The parts are highly versatile and have a wide range of uses.

Deutz Diagnostic Tool Communicator for Deutz Engine DECOM Controllers

With the gradual application of electronic technology, the environmental adaptability of diesel engines has gradually increased. Compared with the FL413F series diesel engines, the technical progress of the FL513 series diesel engines mainly includes the following aspects.

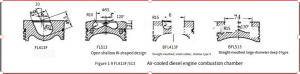

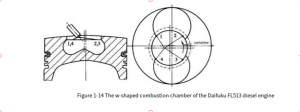

(1) Improvement of combustion chamber The FL513 series air-cooled diesel engines have undergone major changes in the structural shape of the combustion chamber (compared with the FL413F model). The combustion chamber of the non-supercharged model has been improved from an oblique cylindrical (U) combustion chamber to a W-shaped combustion chamber; although the supercharged models all have W-shaped combustion chambers, their structural dimensions have changed significantly, as shown in Figure 1-9.

Through the improvement of the combustion chamber, the diesel engine's combustion system has been improved and the combustion has been more complete, thus greatly improving the various performance indicators of the diesel engine.

2024 Deutz SerDia 4.0 SerDia2010 14.1.9.3 Highest Level 6 Diagnostic Software

(2) Improvement of the fuel supply system

①The A-type pump was changed to a P-type pump, which increased the pump oil pressure (the plunger diameter was increased).

②Injector nozzle improvement. The nozzle holes of the non-supercharged diesel engine were changed from 2 holes to 4 holes, and the injection pressure was increased.

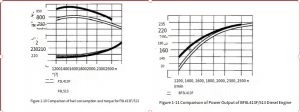

③Reduced fuel consumption and improved torque characteristics, as shown in Figure 1-10.

(3) Improvement of output power

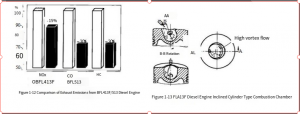

The FL513 model basically retains the basic structural features of the FL413F model: V-type 90° angle, also divided into inline 5, 6 cylinder, V-type 6, 8, 10, 12 cylinder supercharged and non-supercharged models. The turbocharged diesel engine has reduced its rated speed (from 2500r/min to 2300r/min) by improving the combustion mode and the injection pump system, while the non-turbocharged diesel engine has reduced its rated speed (from 2500r/min to 2300r/min) by increasing the cylinder diameter (from 125mm to 128mm), improving the fuel supply system (injection pump) and the combustion mode. The rated power has not only remained unchanged, but also widened the power output range of the diesel engine, thereby greatly improving the adaptability, reliability and service life of the diesel engine. In addition, the overall noise of the diesel engine has also been reduced. The power comparison curve of the BF8L513 and F8L413F diesel engines is shown in Figure 1-11. (4) Improvement of exhaust emission indicators After a series of improvement measures, the exhaust indicators of the FL513 model have been greatly reduced compared with the FL413F model, as shown in Figure 1-12. The emission indicators of the FL513 model have been greatly improved and can meet the requirements of the Euro II standard.

Deutz Serpic 2012 EPC Download & Installation Service Finial Version

(5) FL413F/513 diesel engine combustion process ① The "D" process of Deutz diesel engine combustion: The axis of the oblique cylindrical combustion chamber (as shown in Figure 1-13) intersects the cylinder centerline at an acute angle. Two oil jets of equal thickness and at an acute angle (28°) are sprayed into the vicinity of the oblique cylindrical combustion chamber wall. The oil jets are blown to the periphery by a strong rotating airflow with an intake tangential velocity of approximately 90 m/s (swirl ratio of approximately 2.6). The oil-air mixture at the center of the combustion chamber has an appropriate concentration and ignites first (the ignition delay period is approximately 2° to 3° crankshaft angle). The oil-air mixture at the combustion chamber wall has a higher concentration and, due to the low temperature, the chemical reaction is controlled and does not ignite immediately. Subsequently, due to the effect of thermal mixing, the combustion gases at the combustion chamber walls flow toward the center. Due to their lower temperature and higher density, the combustion gases at the center are flung toward the chamber walls by the centrifugal force of the swirling vortex, remixing with the denser fuel-air mixture at the chamber walls and further burning. The Deutz "D" combustion process is characterized by low combustion noise, avoidance of combustion shock during startup, reliable startup at ambient temperatures above -15°C, good fuel economy, and low thermal load. The Deutz "D" combustion process is used in the FL413F series non-turbocharged diesel engine. ②Deutz diesel engine combustion "Z" process. The Deutz "Z" process utilizes a W-shaped combustion chamber (as shown in Figure 1-14). Fuel is injected directly into the combustion chamber at high pressure through a four-hole injector. The fuel-air mixture is formed by the axial rotation of the air along the cylinder liner (swirl ratio 1.7 ± 0.2) and the "squeeze turbulence" inherent in the combustion chamber.

(6) FL513/413F Diesel Engine Main Technical Parameters The FL513/413F series air-cooled diesel engines have a wide variety of models, and only some models are included. Their main technical parameters are shown in Table 1-1.

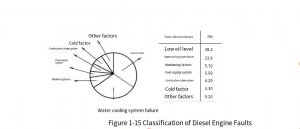

(7) Structural features of FL513 series air-cooled diesel engines ① High degree of standardization, serialization and universalization. The commonality of all engine parts is very high, reaching more than 67% by type and about 85% by number. Whether it is a 6-cylinder engine, an 8-cylinder engine or a 12-cylinder engine, except for the crankcase, crankshaft, camshaft, oil pan, injection pump and intake and exhaust pipes, other parts are universal or basically universal. ② Simple structure and easy maintenance. The one-cylinder-one-head structure facilitates maintenance services such as cylinder pulling, replacement of pistons, cylinder liners and piston rings, and adjustment of valve clearance. ③ Long service life, good reliability and low failure rate. Due to the use of an air cooling system, the failure rate of the cooling system is greatly reduced. Compared with water-cooled diesel engines, the failure rate is reduced by about 34% (as shown in Figure 1-15). The service life can reach more than 10,000 hours. When used on railways or in construction machinery, this series of diesel engines operates at reduced power, with actual operating power at least 10% below rated power. This further extends the engine's service life and significantly reduces the likelihood of engine failure and damage. ④ Low noise and exhaust pollution. This series of diesel engines utilizes advanced combustion theories and noise reduction technologies, resulting in significantly lower noise levels than water-cooled diesel engines of the same power while also significantly reducing emissions. The low-pollution (FL513W) model of this series of diesel engines boasts very high emission standards, making it particularly suitable for use in underground mines and tunnels, and is highly sought after by users. ⑤ Excellent economic performance. This series of diesel engines boasts a fuel consumption rate of 225g/kW·h under rated conditions and a minimum fuel consumption rate of 216g/kW·h, representing oil consumption less than 1% of total fuel consumption. Furthermore, their reliable service life and low failure rate significantly reduce the engine's operating costs, further improving its overall economic performance. ⑥ Good power performance and strong adaptability. a. Strong environmental adaptability: Can be used normally in an ambient temperature of -40-50°C.

b. Wide power range (64 to 386 kW), meeting a variety of applications. This series of diesel engines is widely used in trucks, construction machinery, mining machinery, luxury coaches, railway maintenance equipment, and special vehicles. c. The output power of the FL513 series air-cooled diesel engine includes fan power consumption, and its output power is close to the net output power of the diesel engine, thus providing excellent power performance.

没有评论:

发表评论