Installation Procedure

Perkins EST Diagnostic Adapter- High Quality

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

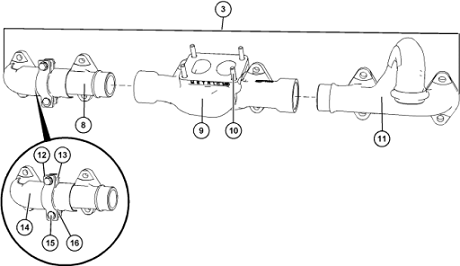

1. Ensure that all components of the exhaust

manifold are free from wear or damage. replace any component that is worn or damaged.

2. If necessary, follow Step 2.a through Step 2.k to

assemble the assembly of exhaust manifold (3)

a. Ensure that Position (X) and Position (Y) for

rear exhaust section (8), center exhaust section (9), and front exhaust section (11) are clean and free from wear or damage.

b. Apply Tooling (A) in Position (X) and Position (Y).

c. Place center exhaust section (9) in a suitable support.

d. Install rear exhaust section (8) to center exhaust section (9).

e. Install front exhaust section (11) to center

exhaust section (9).

f. If necessary, Apply Tooling (A) to taper lock

studs (10). Install taper lock studs to center

exhaust section (9). Tighten the taper lock studs to a torque of 18 N·m (159 lb in).

g. If necessary follow Step 2.h through Step 2.k to install heat shield (14) to rear exhaust section

(8).

h. Position heat shield (14) onto rear exhaust

section (8).

i. Install, bracket (12), bracket (13), and spacers (16).

j. Install nuts and bolts (15) to bracket (12) and

bracket (13). Ensure heat shield (14) is correctly positioned onto rear exhaust section (8).

k. Tighten nuts and bolts (15) to a torque of

55 N·m (41 lbft). Ensure that heat shield (14) remains correctly positioned on rear exhaust section (8)

2023A& 2022A Perkins EST Electronic Service Tool Diagnostic Software Full Provide Installation Service

3. If necessary, apply Tooling (A) to the threads of taper install taper lock studs (7). Install the lock studs to the cylinder head. Tighten the taper lock studs to a torque of 18 N·m ( 159 lb in).

4. Install new gaskets (6), sleeve assemblies (5), and new gaskets (4).

5. Install Tooling (B) in positions shown in Illustration 164 .

6. Install the assembly of exhaust manifold (3).

7. Install spacers (1). Apply Tooling (A) to the threads of new locknuts (2) and install the nuts.

8. Tighten locknuts (2) to a torque of 35 N·m (26 lbft) in the numerical sequence shown in Illustration

164 .

Exhaust manifold tightening sequences and Tooling (B) position

Perkins Engine ECM ECU Flash Files Collection Download

End By:

a. Install the water temperature regulator housing. Refer to Disassembly and Assembly, “Water

Temperature Regulator Housing - Remove and Install” for the correct procedure.

b. Install the turbocharger. Refer to Disassembly

and Assembly, “Turbocharger - Install” for the

correct procedure.

c. Install the NOx Reduction System (NRS)

exhaust cooler. Refer to Disassembly and

Assembly, “Exhaust Cooler (NRS) - Remove

and Install” for the correct procedure.

没有评论:

发表评论