Catalyst (SCR) - Remove

2023A& 2022A Perkins EST Electronic Service Tool Diagnostic Software Full Provide Installation Service

Start By:

a. Remove the temperature sensor for the

catalyst inlet. Refer to Disassembly and

AssemblyTemperature Sensor (Catalyst Inlet) - Remove and Install for the correct procedure

WARNING :

Hot engine components can cause injury from burns. Before performing maintenance on the en-

gine, allow the engine and the components to

WARNING:

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particu-

late Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Perkins Engine ECM ECU Flash Files Collection Download

1. Disconnect the Original Equipment Manufacturer (OEM) exhaust system from connection (3) on Selective Catalyst Reduction (SCR) (5). Refer to the OEM for the correct procedure.

2. Loosen clamp assembly (1) for flexible exhaust pipe (2) to allow removal to SCR catalyst (5).

3. Disconnect clamps (4) from SCR catalyst (5).

4.Attach Tooling (A) and a suitable lift equipment to SCR catalyst (5). The weight of SCR catalyst is approximately 53 kg (117 lb). Ensure that the

SCR catalyst is correctly balanced.

5. Use the suitable lift equipment to remove SCR

catalyst (5). Ensure that flexible exhaust pipe (2) is not strained as the SCR catalyst is removed.

6. Remove clamp assembly (1) from flexible exhaust pipe (2).

7. If necessary, follow Step 7.a through Step 7.c to remove flexible exhaust pipe (2).

a. Loosen clamp assembly (7) for flexible exhaust pipe (2).

b. Remove flexible exhaust pipe (2). Ensure that the flexible exhaust pipe is not strained as the flexible exhaust pipe is removed.

c. If necessary, remove cover (6) from flexible exhaust pipe (2).

Perkins EST Diagnostic Adapter- High Quality

8. If necessary, follow Step 8.a through Step 8.b to remove clamps (4).

a. Make temporary marks on clamps (4) for

installation purposes.

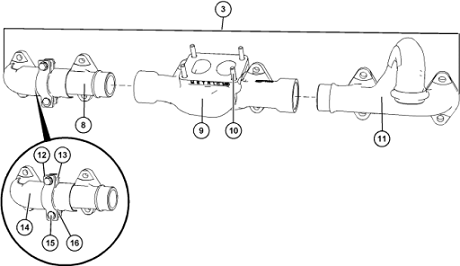

b. Remove clips (8) from pins (9) and remove

clamps (4) from the bracket.

c. Follow Step 8.a through Step 8.bto remove remaining clamps (4).