This paper introduces the disassembly And assembly of the clutch K1,K2,K3,K4 of Doosan transmission part

Disassemble Clutch-K1,K2 and K3

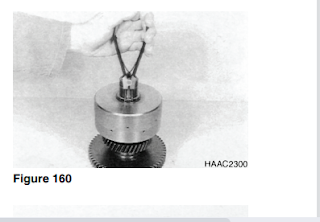

NOTE: The following Figures show the disassembly of the clutch K31. The disassembly of the clutches K1 and K2 is analogous.

Squeeze rectangular ring(Figure 150) out.

2. Pull tapered roller bearing from the shaft.

3. Remove opposite tapered roller bearing accordingly, see Figure 151 and Figure 151.(S) Grab sleeve-5873 001057

(S) Grab sleeve(K3-on output side)-5873 001 058

(S) Basic set-5873 001 000

4. Remove running disk, axial needle cage and axial washer.

5.Remove idler gear.

6. Remove both needle bearings and axial bearing(compl.).

7.Squeeze snap ring out and remove plate pack.

8. Preload compression spring, squeeze retaining ring out and remove components.

(S) Assembly aid(K2 and K3)-5870 345085

(S) Assembly aid (K1)-5870 345 086

(S) Set of extemal pliers-5870 900015

Allison DOC 2021 v5 Transmission Diagnostic Software

9. Press piston out of the plate carrier, using compressed air.

(S) Pry bar-5870345065

Disassemble Clutch-K4

1. Squeeze rectangular ring out and pull tapered roller bearing from the shaft.

2. Remove opposite tapered roller bearing.

(S) Grab sleeve-5873 001057

(S) Basic set-5873 001 000

3. Squeeze retaining ring out and remove plate carrier from the shaft.

(S) Assembly aid-5870345085

(S) Set of extemal pliers-5870 900015

4.Squeeze snap ing out and remove plate pack.

Bendix Acom Pro 2022.v1 diagnostics woftare

5. Preload compression spring, squeeze retaining ring out and remove components.

6. Remove piston.

NOTE: The separation of shaft and gear is not possible

(shrink fit).

(S) Assembly aid-5870 345085

Disassemble Input Shaft

1. If necessary, press turbine shaft out of the input shaft.

NOTE: The turbine shaft is axially fixed using a snap ring which wil be destroyed at the pressing out.

2. Squeeze rectangular ring out and pull off the tapered roller bearing.

3. Pull off the opposite tapered roller bearing.

NOTE: The separation of input shaft (1, Figure 164)

and gear(2) is not possible(shrink fit).

(S) Grab sleeve-5873 001 058

(S) Basic set-5873 001 000

BENZ DTS MONACO 8.16+DATABASE