(1) The SAA6D125E-3 diesel engine complies with strict emission regulations: US EPA standards (2001 regulations), European 2002 regulations, and Japanese construction equipment 2003 regulations. It is a high-performance, high-efficiency, low-fuel-consumption, low-noise diesel engine with improved exhaust color and improved acceleration performance.

2024 HITACHI All in One Tool 3.13 with MPDR 3.32+Security 3.17

(2) Both the SAA6D125E-3 and SAA6D107E-1 diesel engines are in-line, 6-cylinder, water-cooled, direct injection diesel engines.

(3) The SAA6D125E-3 and SAA6D107E-1 diesel engines use an electronically controlled common rail fuel injection system, which injects high-pressure fuel at a pressure of 118MPa, providing optimal injection control to match speed and load, thereby improving diesel engine emission performance and reducing fuel consumption and noise.

(4) The piston is made of high-quality steel and cast in a vibration cooling furnace, with Komatsu's traditional minimum thermal expansion, which improves diesel engine reliability and life.

(5) The SAA6D125E-3 and SAA6D107E-1 diesel engines use an electronically controlled common rail fuel injection system and an optimal divergence characteristic design during low-temperature starting, which improves starting performance and reduces white smoke emissions.

(6) The turbocharger used in the 125E-2 diesel engine has been improved so that the air supply cycle can control the impact of the compressor end, optimize performance, and have a wider speed range from low speed to high speed, and lower fuel consumption.

Hitachi Workshop Service Manual 2019 PDF Download

(7) The thickness of the top surface of the cylinder block has been increased to prevent deformation after long-term operation and make remanufacturing easier. In addition, the main body rigidity has been improved by increasing the rigidity of the main ribs, reducing deformation and vibration under load and preventing the generation of various noises.

(8) The fuel pump size of the electronic common rail fuel injection system is 1/3 of that of the ordinary inline fuel injection system. In addition, the mounting seat is replaced by a flange, which is tightly connected to the timing gearbox to reduce noise.

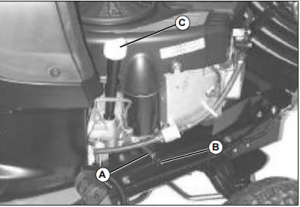

(9) The air filter is changed from a common end face seal to a radial seal to prevent dust from entering and damaging parts. In addition, the 5-segment display type air filter clogging sensor can provide accurate information on the cleaning time.

(10) The oil filter is a high-performance and high-efficiency filter.

(11) The fuel filter is a high-performance and high-efficiency special fuel filter that can filter out small particles of dirt and protect the electronic common rail fuel injection system

(12) If the electronic control unit determines that the diesel engine is operating abnormally, a warning will be issued and the system will be switched to emergency escape mode.

(13) When the diesel engine is started at a very low temperature, if the diesel engine speed suddenly increases, overloading will apply excessive load to the bearings before sufficient lubrication, which will reduce the service life of the diesel engine. In particular, overloading will damage the

floating bearing of the turbocharger. In order to prevent this from happening, a turbine protection system is installed to limit the diesel engine speed.

Hitachi Excavator Diagnostic Tool for ZX-5A ZX-5B ZX-5G ZX-1 ZX-3 Series