How to inspect the caterpillar325c excavator air intake and exhaust system

1. Inspection of air intake and exhaust systems

2023 CAT ET 2023A 2022A & 2019C Full Service Download and Installation Service

(1) Inspection of air intake resistance. If there is resistance in the intake and exhaust systems, it will be the 1U-5470 engine pressure assembly (Figure 3-1-46).

1) Check the intake pipe and exhaust pipe of the engine air filter to ensure that the pipes are not leaking.

2) Check the engine air filter element. Use a clean engine air filter

3) Check whether there are traces of dirt on the clean side of the engine air filter element. If traces of dirt are observed, it means that the contaminants have entered the engine air filter element and/or filter element seal. . NOTE: Hot engine parts can cause burns. Allow the engine and parts to cool before servicing the engine. Contact with a running engine can result in burns from hot parts or damage from rotating parts. When working on a running engine, avoid contact with hot or rotating parts.

4) Measure using the differential pressure gauge in the 1U-5470 engine pressure test assembly

①As shown in Figure 3-1-50, connect the vacuum port of the differential pressure gauge to test position 3. Test location 3 may be anywhere on intake manifold 2 behind engine air filter 4 and in front of wheel booster 1.

12.2021 Caterpillar ECM ECU Flash Files Full Set Download

②Open the pressure port of the differential pressure gauge to allow it to communicate with the atmosphere.

③Start the engine. Run the engine at high idle speed with no load.

④Record the pressure value, multiply this pressure value by 1.8, and then compare it with the corresponding value below. There is resistance to airflow through an old engine air filter. There will also be some resistance to airflow through a clogged engine air filter. in In the above two cases, the resistance must not exceed 6.2kPa; the resistance of the air flowing through the new air filter element must not exceed 3.7kPa.

(2) Inspection of exhaust resistance. Back pressure is the pressure difference between the exhaust pressure at the elbow outlet and the atmospheric pressure. The tools required to check exhaust resistance are 1U-5470 engine pressure components (Figure 3-1-46). NOTE: Hot engine parts can cause burns. Allow the engine and components to cool before servicing the engine. Contact with a running engine can result in burns from hot parts or injury from rotating parts. When working on a running engine, avoid contact with hot or rotating parts. Use the differential pressure gauge in the 1U-5470 Engine Pressure Test Assembly to measure exhaust backpressure. Use the following steps to measure exhaust back pressure.

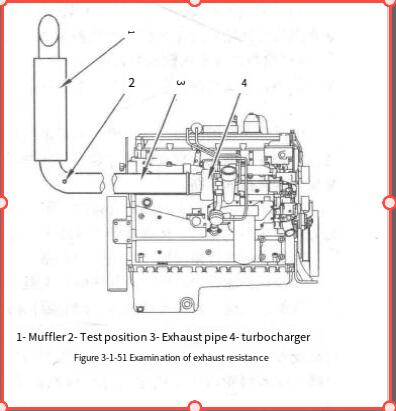

1) As shown in Figure 3-1-51, connect the vacuum port of the differential pressure gauge to test position

CAT Caterpillar ET 4 Diagnostic Adapter Truck Diagnostic Tool-high quality

2. Test location 2 may be anywhere on exhaust pipe

3 behind turbocharger 4 and in front of muffler

1. 2) Open the pressure port of the differential pressure gauge to allow it to communicate with the atmosphere.

3) Start the engine. Run the engine at high idle speed with no load.

4) Record the pressure value.

5) Multiply the value in step 4) by 1.80.

6) Compare the value in step 5) with the value below. The exhaust back pressure must not be greater than 10.OkPa.