This Article Mainly Introduces Cummins CFP11E series Fire Pump Drive Engine change the fuel filters Replace Steps

Cummins INSITE 8.7 Pro 2021 Electronic Service Diagnostic Software

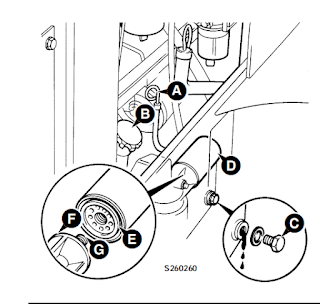

As shown in Figure 5-4, inspect the fuel injection pump mounting nuts (including the support bracket) for loose

or damaged hardware. Inspect the fuel line hoses and fuel filters for wear, damage, loose fittings, and leaks.

Repair or replace damaged hoses and filters as required.

Cummins INLINE 6 Data Link Adapter Truck Diagnostic Tool

Engine fuel is highly flammable and represents an extreme hazard for fire or explosion when exposed

to electrical sparks or open flame. Clean up spilled fuel immediately. Keep sources of electrical spark

or open flame away from a fuel source.

Do not open the fuel filter/water separator drain valve or dismantle the fuel lines on the high-pressure

fuel system with the engine running. High pressure fuel spray from an operating engine can cause

serious personal injury or fire hazard.

To change the fuel filters:

1. Shut off the engine.

2. Close any fuel valves (if equipped) to prevent fuel from draining or siphoning.

3. Clean the area around the fuel filter or fuel/water separator heads.

NOTE: Refer to the engine data sheet for filter replacement recommendations.

4. Remove the spent filter canisters using a filter wrench.

5. Clean the filter mounting head surfaces of sludge buildup and foreign particles. Ensure mating gasket surfaces are clean.

6. Lubricate the gasket seals with clean SAE 15W-40 lubricating oil.

7. Center the filter ring on the threaded mounting nipple. Screw the filter canister onto the mounting flange

until the gasket is snug against the mounting flange, then tighten an additional 1/4 turn.

8. Open the fuel supply valves (if equipped).

Mechanical over-tightening can distort the threads or damage the filter element seal.

9. Press either the CRANK BATT A or CRANK BATT B button to start the engine to allow the fuel to flow

through the system.

10. Depress the contactor switch for up to fifteen seconds or until the engine starts. Repeat up to three times,

if necessary